|

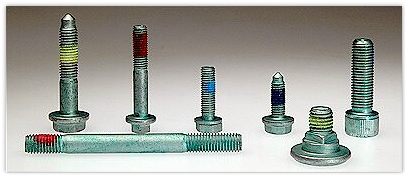

The Torque’N’Tension UV Fluid is formed by a

watery liquid base made-up of virtually neutral substances.

It is applied to threading retainers which were previously protected

against corrosion by protective coatings (hot-dipping galvanisation,

mechanical or electrolytic galvanisation, organic and non-organic

coating).

Once applied, Torque’N’Tension UV Fluid forms a dry, non-sticky film

detectable to UV rays.

The lubricant’s target is to reduce the tension factor of the coated

parts, and to control the tension during the assemblage with a set

torsion rate.

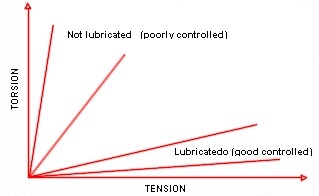

The diagram illustrates the total power rotation (torsion) needed to

stretch out a galvanised fastener.

The non-lubricated fastener needs a

greater torsion to tighten, and this is quite inconceivable without

ruining the fastener in the attempt to reach the desired tension. A

correct lubrication of the fastener brings about conceivable and

reproducible torsion-tension performance. This provides safer joints

for torsion controlled clamps.

Torque’N’Tension UV Fluid is applied to high-resistant coated

clamps, in application, where rotating or nut clamp systems are

used, and where there’s a need to control the rotating assemblage

capability of bolts, nuts and washers.

Torque’N’Tension UV Fluid doesn’t evaporate, is non-toxic and

colourless. It is easy to handle and remains on the parts until

their employment.

ADVANTAGES:

|

- verifiable lubricant film

- easy to use

- low-cost

- safe and secure

- easy to handle

|

go

to the products pages |